Stellapps Technologies, the company set to disrupt dairy farming in India

The five co-founders of Stellapps knew each other since their very first jobs at Wipro Technologies. In their late 30s and early 40s, they realized that ‘if not now, then never’ and that they ‘need to step out and do something now’.

Frequent discussions among the prospective co-founders helped in narrowing down the vision to ‘work toward the improvement of life’ and their technical expertise left them with options of working on something related to agriculture and health. In April 2011, the idea was further filtered and Stellapps Technologies Pvt Ltd was registered. Today, Stellapps is India’s first dairy technology solutions company, building automation tools integrated with cloud, mobility, and data analytics for dairy farms, cooperatives, and private dairies.

Stellapps Technologies is funded by Omnivore Partners and was incubated at IIT Madras’ Rural Technology Business Incubator (RTBI). Stellapps has not only uniquely positioned itself as a niche company but its idea and market have been validated in its three years of existence by drawing good number of clients and funding at right stages.

The market and the focus

India accounts for 16% of the global milk production. However, the dairy farming industry is highly fragmented with the average size of herd being 2-3 milch animals. The majority of farmers can be categorized as small/medium sized.

Dairy farm is a huge vertical and Stellapps has done its homework well. They are targeting the small and medium farmers (who own five to 25 cows) who don’t have any technology intervention/support. Stellapps is offering solutions in milk production stage and keeping a distance from the marketing of the produce. Unlike any other profession, dairy farmers end up working for more than eight hours a day and still remain non-profitable. Stellapps solutions include multiple automation and knowledge-based solutions which optimize the milk production process and keep a check on the health of the cattle.

Understanding the problem

Since the cattle is the central element in milk production, it is extremely important to see that it is:

a) Healthy;

b) At an optimum level of productivity;

c) Optimally provided fodder, water and healthy housing

If a farmer is aware of the above parameters, dairy farming will be profitable.

Traditionally, dairy farming is considered a labor intensive industry where one has to put a large labor force in order to get more yield. It’s a big myth since the yield can be increased by merely maintaining cleanliness, feeding the cattle at right times, automating most of the processes and installing chiller in the milk production plant. Though it might need electricity but the biogas produced from the cow dung can generate enough power.

Products and technology

Stellapps’ products are designed to optimize the entire milk production process right from setting up the right kind of infrastructure and housing facilities for cattle, to fulfilling the power requirements by setting up biogas power plants.

Stellapps’ products include:

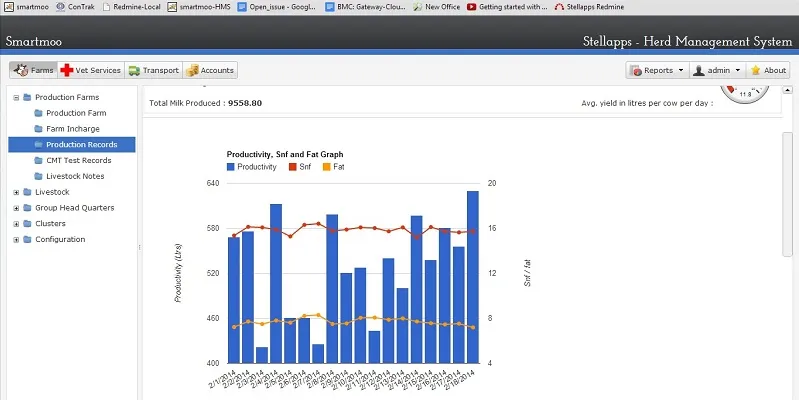

SmartMoo

It’s an end-to-end dairy farm services product with focus on clean milk production protocols, productivity improvement, cost optimization and real-time data access. It includes:

- Automated Milking System (SmartAMS)

- Bulk Milk Chilling System (SmartBMC)

- End to end farm setup services (cow comfort infrastructure and housing, cow selection, silage, vermicompost, veterinary & para-veterinary services)

- Farm Layout Design & Modelling (cow shed, milking parlours and labour quarters)

- Consulting for productivity improvement and input cost optimization

- Bio Gas setup for off-grid farm power

- Farm management equipment (Hoof trimmers, De-horners, Foot-bath, Groomers, Anti-kick bar, Cleaning-in-Place solutions)

Other products include:

smartFarms: It’s a cloud based farm and herd management system for animal recording, productivity and peak-yield management, breeding, preventive health care, fodder and veterinary care.

smartBMC: It’s a premium milk chilling equipment with internet and mobile enabled management.

smartAMS: Basically a milk line based automated milking systems (AMS), it starts from a simple 3 station parlour to large herring bone parlours bundled with cow identification, automated milk meters, cluster retrieval and milk sampling – enabling Udder-to-Cup clean milk production protocols.

ConTrak: It enables internet based, real-time management of cold-chain with enhanced reporting, pilferage reduction & tamper proofing features, as applicable to Bulk Milk Coolers (BMCs), Silos and Cold Rooms

Pricing and tech adaption

Stellapps enjoys a competitive pricing advantage as compared to similar technology providers (typically overseas). The pricing includes the entire budget right from the infrastructure development to the milking and storage. Since the complete analysis takes place on cloud, the farmer has little to do to understand the information being transmitted from the sensors (placed on cattle and chilling systems) to the veterinary experts. Data is transferred via wireless networks to Stellapps servers and can be monitored through their Android apps.

Stellapps follows the philosophy of working with the farmer where they make profits only when a farmer makes profit. Their revenue is derived from a fixed share per litre of milk production from a profit making farmer. This way, it doesn’t pinch the farmer and Stellapps manages to keep their skin in the game.

Co-founders’ backgrounds

Ranjith Mukundan is the CEO & Managing Director. He’s a telecom & software engineer who has lead a team of 250 people as part of the Wipro Telecom Application Practice and has 17 years of industry experience.

Ravishankar Shiroor is Director & Business Development Head. An IIT-Madras alumnus, he has 20+ years of industry experience in embedded software and telecoms. He has been a strategy advisor at AT&T, Telstra, Nortel, Ericsson, and Alcatel-Lucent.

Praveen Nale is Director & Chief Technology Officer. He’s also an IIT- Madras alumnus with 15+ years of industry experience in Hardware, Embedded Software and Telecom. He has the unusual combination of hands-on exposure to both hardware and software.

Ramakrishna Adukuri is the Head of Software Solutions. He is an IIT-Kharagpur alumnus with 15+ year of industry experience in Telecoms and Enterprise Architecture. He has been the chief Architect of unified communications & Cloud.

Venkatesh Seshasayee is the Head of Domain Solutions. He has 15+ years of industry experience, including that of Chief Architect of Service Delivery Platform (SDP) technology deployed in many telecom service providers' networks.

Value Proposition

- Cost effective end-to-end Dairy Farm solution: Powered by patent pending technologies, Stellapps has broken some compelling price barriers to ensure that world-class dairy automation solutions are available at emerging market price points.

- Cost reduction: Reduced input costs by ensuring automation of milking procedures and making things less dependent on external labour. Fodder management modules to ensure low input cost per litre (and optimizing dependency on expensive external feeds)

- Preventive Healthcare: Advanced cloud-based analytics ensures sub-clinical intervention and significant reduction in sickness incidents. Thereby, increasing herd milk productivity levels.

- Peak yield management: Advanced activity meters & cloud-based analytics ensures better heat detection (ovulation cycles) to manage lactation cycles better and reducing inter-calving periods. Thereby, significantly increasing productivity levels.

- Improved Cull Value - Data recording of all herd parameters ensures that the cows fetch a significant premium when sold.

- Reduced Insurance Premium – Real time view of herd data and reliable data recording mechanism helps reduce cattle insurance premium by over 50%.

- Premium Milk production - Controlled and tamper proof cold-chain management (e.g., remote controlled bulk milk coolers) helps ensure that the bacterial load is minimized and the milk (and byproducts) can be sold as a premium product.

What has worked for Stellapps

Though nothing can take away the credit from the incredible team at Stellapps, there are certain factors which have favored the company. This will definitely help the entrepreneurs venturing into agriculture and dairy farming to understand this space well:

- Patience: The co-founders and the investors very well understand that there are no immediate returns in this industry.

- More number of founders: This has definitely helped in providing the initial stability as each co-founder used to put up 20-30% of their salary to support this initiative (from Nov 2010 to Oct 2011). Their collective experience has come very handy as well.

- Support from family, and IIT-Madras (Rural Technology Business Incubator).

- Good timing: India lags far behind when compared to developed nations in terms of technology adaption in dairy farming industry and there’s a massive gap which can be addressed by providing technology enabled solutions.

- Market response: Till now, the farmers have been extremely receptive towards the Stellapps solutions which will play an important role in the long term as they will themselves act as the best marketers of the product.

- Government subsidy for clean milk production.

Within a short span of three years, Stellapps has installed world’s largest community milking parlor in Chintamani Taluk (Chikkaballapur district) where 200 cows are milked per day. This is just an addition to the assurance about the promising future of the company.

Were you aware of Stellapps Technologies before? We would love to hear about some of the unconventional innovations you’ve heard of so far.